The Indian Space Research Organisation (ISRO) has conducted a successful firing test of a 3D printed PS4 liquid rocket engine. The engine will be used on the upper stage of the Polar Satellite Launch Vehicle (PSLV).

The PS4 engine, fuelled by a mixture of nitrogen tetraoxide and monomethylhydrazine, successfully fired for 665 seconds during the test at the Mahendragiri test facility. The test data has been provided by ISRO.

The engine was developed by ISRO’s Liquid Propulsion Centre (LPSC) and its physical prototype was built by India’s Wipro 3D. It is noted that LPSC modified the existing engine design, which was earlier used for the first and fourth stage of PSLV.

Additive technologies including 3D printing and a new method of laser cladding of powder materials were used in the manufacturing process. This reduced the number of parts from 14 to 1 and reduced the number of welds. This approach significantly saved on raw material consumption – only 13.7kg of metal powder was used, while the traditional production method would have required around 565kg of metal. In addition, the new method allowed to speed up production by 60 per cent.

Earlier, experts conducted four successful firing tests of the assembled engine design, which confirmed its performance parameters. These 74-second tests were an important step in the development of additive manufacturing technologies for future rocket engines, ISRO said.

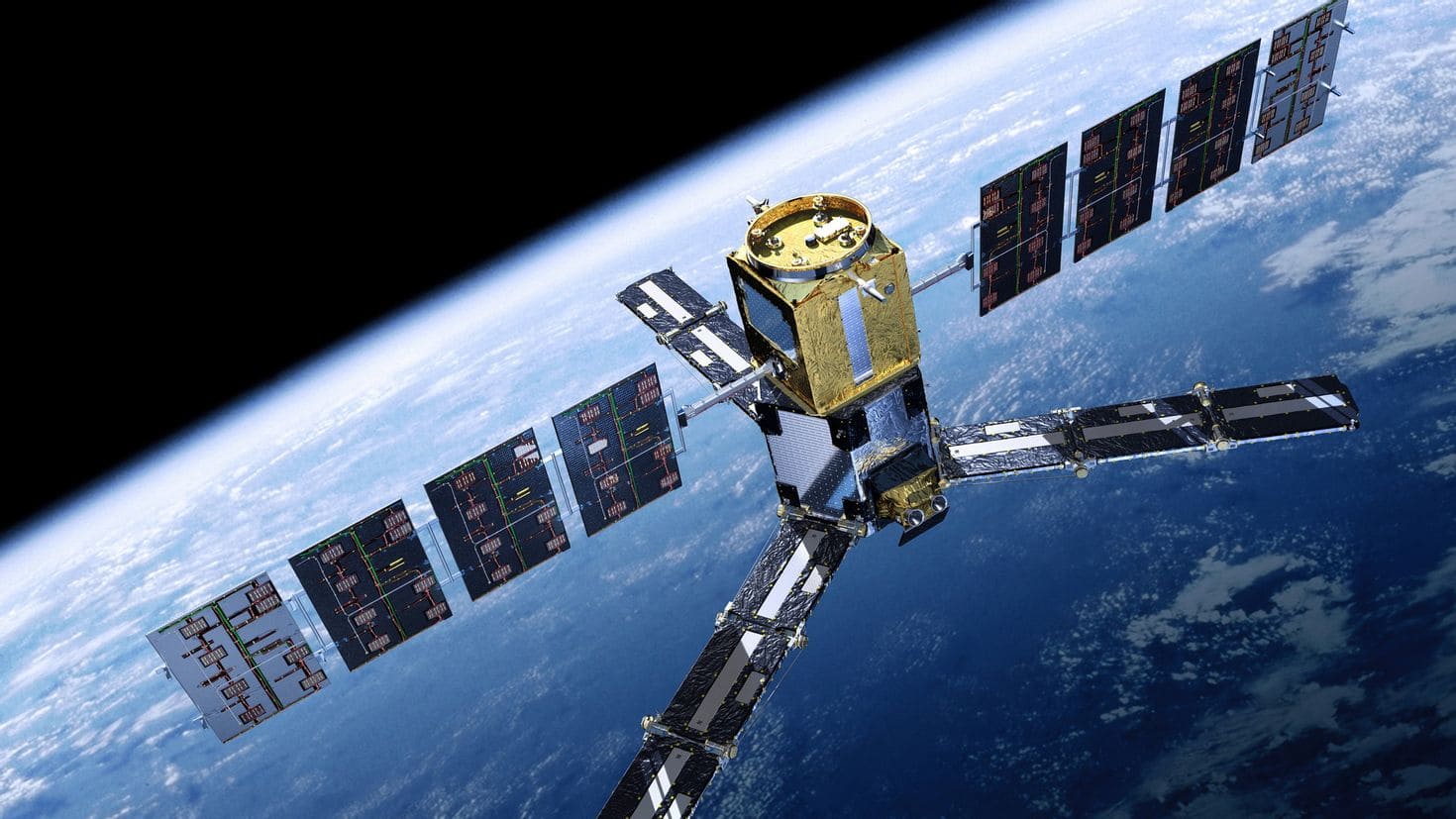

The 44-metre tall Polar Satellite Launch Vehicle (PSLV) is one of India’s main launch vehicles, along with the LVM-3. The rocket is capable of delivering up to 3,800kg of payload to low Earth orbit and up to 1,750kg to a 600km-high sun-synchronous orbit. PSLV has four different configurations for different purposes – PSLV-CA, PSLV-DL, PSLV-QL and PSLV-XL, which differ in the number of side boosters.

China has previously tested 3D-printed engine components in space. A 3D-printed fuel tank on board the Tiangdu-2 communications satellite demonstrated successful operation.